Some Engineering projects at Berkeley Lab are enormous undertakings – requiring many years, and an army of experts across engineering and technical disciplines to bring science to life. Other projects are quite the opposite – requiring targeted and efficient engineering support that can serve as a springboard for science. This second type of project, which might only need a little engineering nudge in the right direction, is exactly the place where Engineering Small Project Support (EsPS), a group that provides ad hoc engineering support at Berkeley Lab, can help.

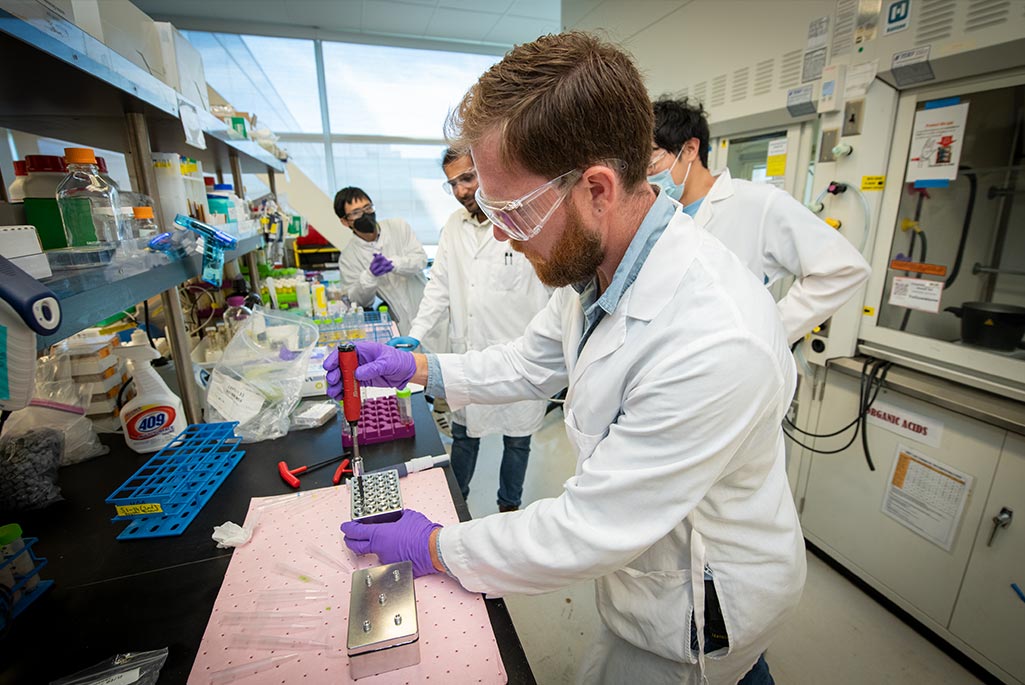

That’s what happened in a recent collaboration between EsPS and the Advanced Biofuels and Bioproducts Process Development Unit (ABPDU). ABPDU team members Chang Dou and Ning Sun, along with Hemant Choudhary, an affiliate scientist from the Joint BioEnergy Institute (JBEI), were looking to develop a small-scale high-throughput chemical reactor, an enclosed vessel that allows experimenters to quickly test an array of chemical reactions at high temperature and high pressure. Mechanical Engineer Nick Wenner stepped in to provide support courtesy of EsPS.

“We were looking for something that will allow us to rapidly test new chemistries at a small scale but with high throughput,” says Dou, a senior scientific engineering associate in the Biological Systems and Engineering (BSE) Division. “Instead of doing one, two, or a couple tests at a time, we wanted to be able to do dozens or hundreds at a time.”

In addition, the team needed a vessel that could maintain high pressure, withstand a range of chemicals, and permit the ability to actively stir the materials inside each well.

“All of these elements are essential to ensure that our small-scale reactions meaningfully inform larger-scale operations, since the same factors are present in full-scale reactors. This is essentially the science of scaling-up, which is the central theme of our research at ABPDU,” adds Sun, BSE staff scientist.

The team was unable to find any off-the-shelf product that met their experimental requirements.

“At ABPDU and JBEI, they have a serial process of steps up in scale for chemical reactions that require high pressure. They have three small reactors with, say, a liter in capacity, and then they have two 10-liter reactors, one 50-liter reactor, and finally a 200-liter reactor,” explains Wenner. “And they’re working with partners to help make the leap from the bench top to a commercial product or process.”

ABPDU and JBEI reached out to the EsPS team to help plug a gap in their scaling process.

“These small-scale batch reactors are a stepping stone to eventually scaling up to something like an Andritz reactor, which is a 200-liter system,” Wenner says. “An Andritz reactor is a big, complicated thing with temperature and pressure control and a stirring bar inside. It is a big deal to run one of these tests with the Andritz reactor. Every one of these 24 little wells is a test tube. This is an opportunity to do a little mini reactor test and screening before you take that larger leap.”

The problem

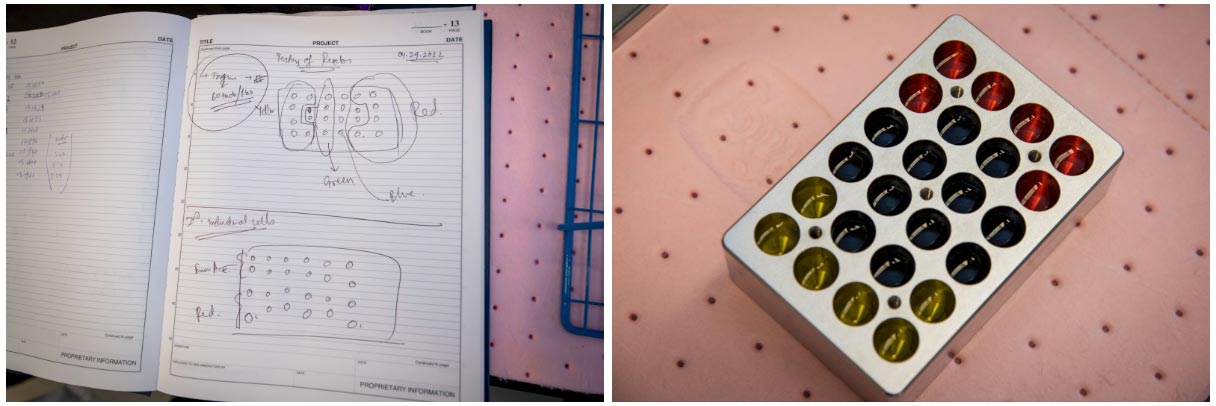

The ABPDU and JBEI teams had an existing small-batch chemical reactor, but it posed a number of issues to the work they were trying to accomplish. The original device was made of plastic, which could not hold enough pressure to achieve the necessary high-pressure, high-temperature reactions. In addition, all 24 wells were sealed by one gasket that was screwed to the top of the reactor. The gasket made it difficult to get a perfect seal, so the device had a propensity to leak. Some of the materials used in experiments caused the lining that sealed the device to deteriorate. And, when the top of the device was lifted after an experiment had been performed, there was a danger that condensation that had formed on the underside of the lid could drip into adjacent wells, jeopardizing the integrity of the experiment.

Knowing all this, Wenner set about defining the requirements for the project, looking to understand what chemicals would be used and what temperatures the chemicals would need to reach, among other things.

“The engineering itself – it’s not a super complicated object, but it’s helping solve a really critical need for the science, while also accommodating a tight timeline and a limited budget,” says Wenner. “And so, we were able to come in and provide this resource. We were able to do some prototyping and find the right approach.”

The solution

Engineering went into each component of the new small-batch reactor. The reactor is made of a base constructed of 316L stainless steel, a material chosen for its affordability, machinability, and chemical compatibility with the intended testing materials. It was designed to match the dimensions of a standard 24-well plate to facilitate compatibility with other systems used for well plates, such as solid and liquid handling systems and heating and stirring systems. Each of the 24 cylindrical wells can accommodate up to 6ml of liquid.

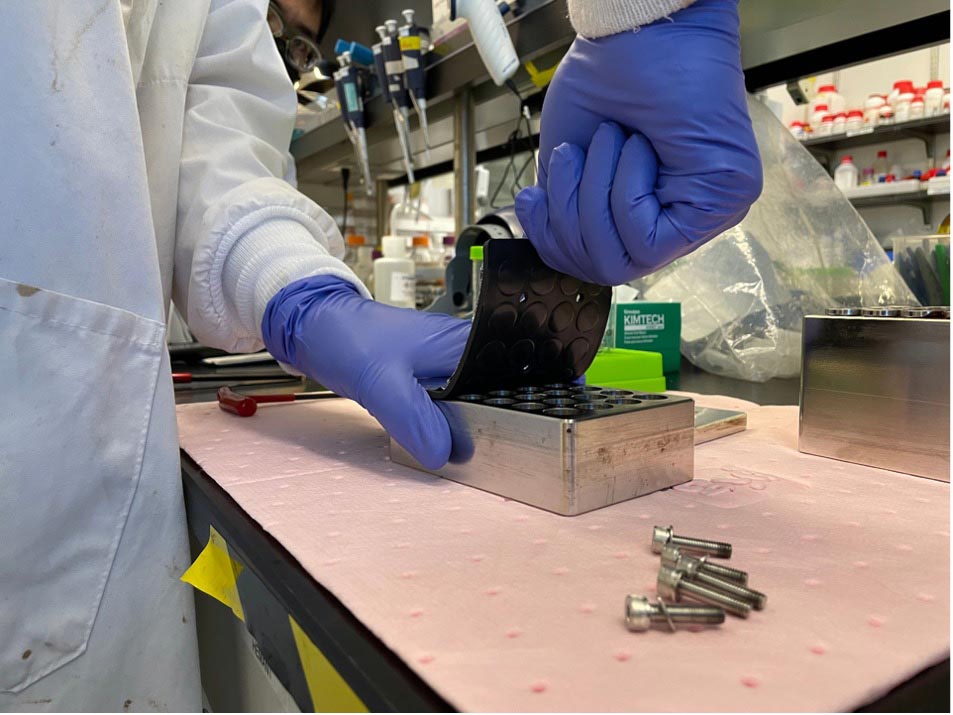

Initially, the design used off-the-shelf caps to plug each of the wells in the reactor individually. Polytetrafluoroethylene (PTFE) O-rings were used to help seal the plug. PTFE was chosen for its chemical compatibility, ability to accommodate high temperatures, resistance to sudden failure, and low cost.

However, an issue cropped up with these components. When the PTFE O-rings were heated and compressed during an experiment, they became deformed. The result was that the O-rings were single use only and needed to be replaced after each experiment to ensure proper sealing. PTFE is a rigid plastic at room temperature, so it was difficult to stretch it over the threads of the cap, making the O-rings time consuming to replace. Wenner and the EsPS team even experimented with creating a special tool to help insert the O-rings, but pushing them into place still resulted in a slightly deformed seal.

Ultimately, Wenner designed a new cap for the small-batch reactor, with threads the O-rings could easily fit over and a well around the rim to contain the seal.

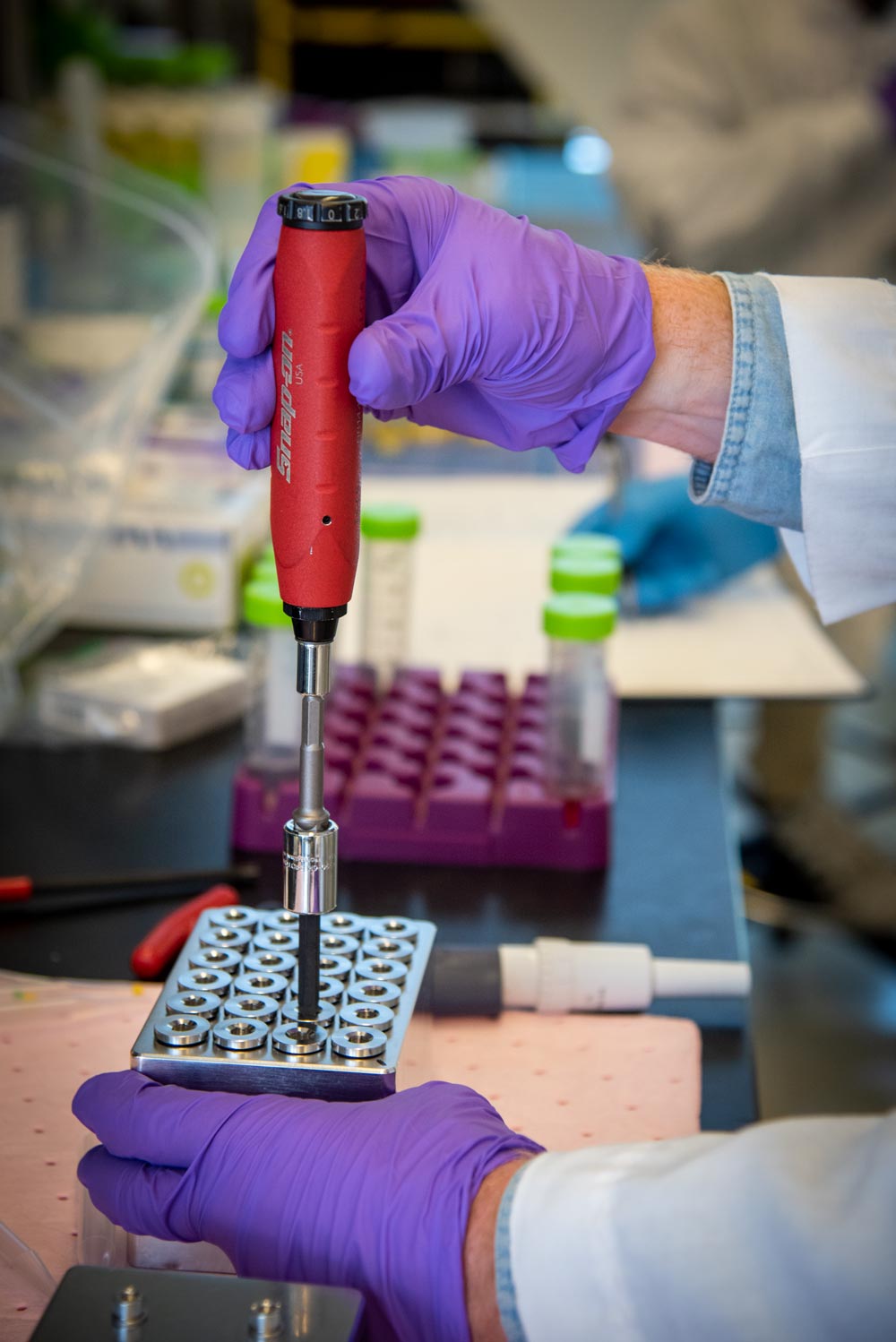

Each cap must be tightened with a specific torque to create an optimal seal. After testing, a torque setting of 15 in-lbs was found to be ideal for the PTFE O-rings.

A torque screwdriver is used to control the applied torque and achieve a proper seal for each well. (Credit: Nick Wenner, Berkeley Lab)

The final components of the small-batch reactor are glass liners, which are used to contain the material for each experiment. The glass liners were custom designed for use in the reactor. They have a small internal lip to facilitate loading and unloading into the wells.

Work on this project began in February of 2022, with the initial designs presented in March of that year – a very tight turnaround compared to many larger-scale projects at the Lab. At the same time, the device has continued to evolve alongside the needs of the ABPDU team, with custom plugs being added in 2025. The EsPS team’s flexibility and location on site allows them to work alongside science partners, enabling the engineering to develop with the needs of the science, and in a way that is cost effective for the projects.

“We use the small-batch reactor for high-temperature, high-pressure reactions, including both lignocellulosic biomass conversion and plastics depolymerization for further upgrading,” explains Sun. “The reactor has been used in multiple DOE-, DoD-, and industry-funded projects, including the research collaboration with JBEI, BioCircular Valley, and X, the moonshot factory. It has contributed to multiple milestones and deliverables.”

What is Engineering Small Projects Support?

Engineering Small Projects Support draws on staff from across the Engineering Division, leveraging the unique expertise within the Division to provide tactical support to areas across the Lab.

“The group provides opportunities for researchers to have engineering support at a range of scales,” Wenner explains. “It could be a long-term project, but it’s often at a small scale. A researcher has an idea, and they need somebody who can quickly and relatively inexpensively turn their idea into a working thing. And you often don’t need a giant project to help move the science forward. And so, it’s an exciting thing to come in, in a targeted way, and just make something that someone can use to make a lot of leaps forward with their research. There’s a big service to the Lab in it.”

The Engineering Division’s matrixing system allows EsPS engineers to spend the majority of their time on larger-scale projects, pitching in to provide engineering support to smaller projects when needed. It also enables engineers to bring skills gained on large projects to other areas of the Lab.

While Wenner is now almost entirely focused on support for SPEC-S5, the Engineering Division has resources available for a wide range of projects that are available across the Lab. Please contact EsPS for more information.